Facing the global automotive industry's push for supply chain decarbonization and digital transformation, Taiwanese fastener manufacturer, Hu Pao Industries Co., Ltd., continues to pursue dual sustainability and efficiency goals through international-level carbon footprint verification, AI implementation, and process optimization. Not only has it successfully positioned itself as a green fastener

supplier with immediate competitiveness in the CBAM era, but it also sets an exemplary transformation model for other SMEs.

Carbon Footprint Verification Completed / Recognized Carbon Reduction Achievements

Achieving an 8.8% increase in spipment volume and a 14.1% reduction in emissions per ton within just two years.

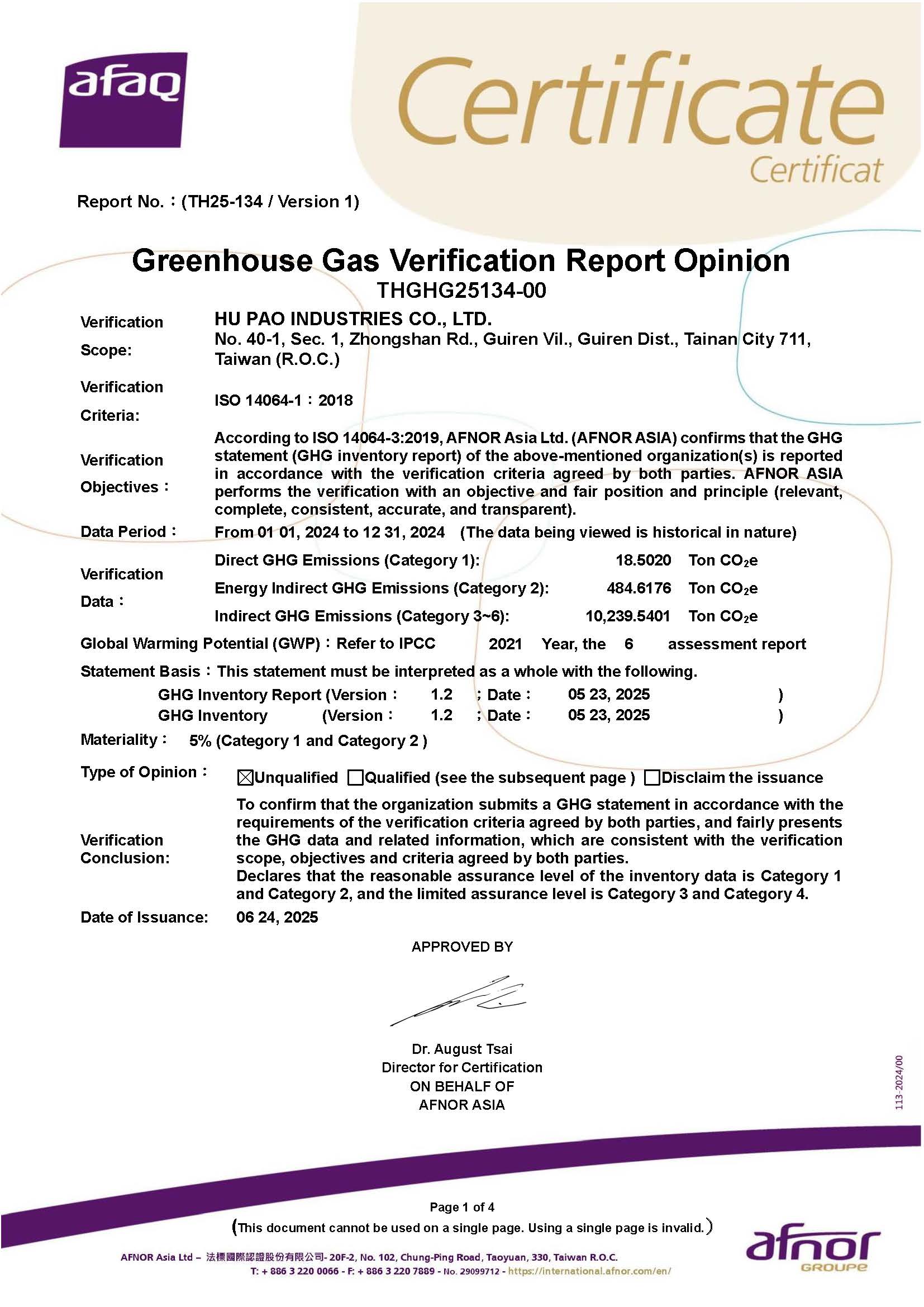

Hu Pao has completed the ISO 14064-1 verification and annually upgrades the quality and scope of its carbon footprint verification. To achieve visual management, its carbon emissions data has been integrated with the internal ERP system. Data verified by ARES in 2022 shows that its carbon emissions from 2,448 tons of shipped finished products reached 10,959 tons (4.47 CO2e/ton). Data verified by French AFNOR in 2024 shows the carbon emissions from 2,663 tons of shipped finished products reached 10,239 tons (3.84 tons CO2e/ton). This demonstrates remarkable performance in maintaining production capacity and quality while achieving an 8.8% increase in shipment volume and a 14.1% reduction in emissions per ton within just two years.

Self-developed “Waste Oil Recycling Trough” Amplifies ESG Benefits

Monthly oil consumption reduced by 20%

Metal forming requires substantial amounts of lubricating oil, but the environmental pollution caused by untreated waste oil discharge has long been a headache for manufacturers. To address this, Hu Pao independently developed a waste oil recycling trough that can filter and store waste oil for reuse, fully implementing green innovation in the manufacturing process. This solution reduces monthly oil consumption by 20% while also lowering workplace safety risks and eliminating unpleasant odors in the factory area, thereby improving environmental quality. Such an innovation earned Hu Pao an honor as one of Tainan City's Top 10 SBIR Outstanding Projects in 2024, establishing it as an industrial benchmark.

Introducing the AI Platform to Enhance Service Efficiency and Accuracy

Vsing the Intellicon Egenthub AI platform to strengthen the management capabilities of quotation effectiveness, of quotation effectivenss, internal quality control, preventive maintenance, etc.

To enhance opera tiona lefficiency and reduce human error, Hu Pao introduced the Intellicon EgentHub AI platform to strengthen the management capabilities of quotation effectiveness, internal quality control, preventive maintenance, etc. Such as initiative also improves its delivery reliability and operational transparency as required by Tier 1 automotive supply chains. For example, the platform automatically parses customers’ RFQ documents and cross-references them with ERP cost data, significantly reducing its quoting time from 120 minutes to just 5 minutes and ensuring consistent quoting logic.

The Sustainable Manufacturing Technology Partner with Differentiated Features

Compared to thousands of Taiwanese fastener manufacturers still in the early stages of ESG implementation, Hu Pao has established a significant competitive edge through its leadership in carbon emission verification, process innovation, AI integration, and internalizing ESG/CBAM into its corporate culture. Beyond conducting annual carbon footprint verification and completing third party GHG verification every 2 years, the company drives internal improvements through innovative processes like waste oil recycling and energy intensity optimization. It also leverages AI to integrate quotation documents and resolve production bottlenecks. Hu Pao’s President and its management team's deep understanding of ESG and CBAM trends has embedded sustainability as a core corporate value. “We don't just produce fasteners; we provide customers with parts backed by credible carbon data and quality traceability, helping them navigate ESG and CBAM requirements with confidence,” said General Manager Bill Wang.

Hu Pao has implemented ESG practices and leveraged AI alongside innovative green manufacturing processes to meet the regulatory requirements of global industrial buyers, successfully demonstrating its value as a technology partner capable of collaborating with the industry to co-create sustainability. For other SMEs, this serves not only as a successful model but also as a benchmark example for Taiwan's fastener industry to enhance competitiveness and advance into the next decade.

Hu Pao contact: General Manager Bill Wang

Email: bill@hupao.com.tw

HU PAO INDUSTRIES CO., LTD. will be exhibiting at several major international fastener and machinery exhibitions.

We sincerely invite you to visit our booth and meet us in person to discuss industry trends and potential cooperation opportunities.

Fastener Fair USA – Phoenix 2026

HU PAO INDUSTRIES CO., LTD. cordially invites you to visit us at Fastener Fair USA – Phoenix 2026, held in the United States from October 7 to October 9, 2026.

Exhibition Name: Fastener Fair USA – Phoenix 2026

Exhibition Dates: October 7–9, 2026

Venue: Phoenix Convention Center

Address: 100 N 3rd St, Phoenix, AZ 85004 US

Booth No.: To be announced

Taiwan International Fastener Show 2026

We are pleased to invite you to visit HU PAO INDUSTRIES CO., LTD. at the Taiwan International Fastener Show 2026, taking place in Taiwan from April 22 to April 24, 2026.

Exhibition Name: Taiwan International Fastener Show 2026

Exhibition Dates: April 22–24, 2026

Venue: Kaohsiung Exhibition Center

Address: No. 39, Chenggong 2nd Rd., Qianzhen Dist., Kaohsiung City, Taiwan

Booth No.: S1316

Fastener Fair Stuttgart 2027

HU PAO INDUSTRIES CO., LTD. warmly invites you to visit us at Fastener Fair Stuttgart 2027, held in Germany from April 6 to April 8, 2027.

Exhibition Name: Fastener Fair Stuttgart 2027

Exhibition Dates: April 6–8, 2027

Venue: New Stuttgart Trade Fair Centre

Address: Messepiazza 1, 70629 Stuttgart, Germany

Booth No.: To be announced

We look forward to welcoming you at the exhibitions and meeting you in person.

HUPAO has successfully completed the ISO 14064-1:2018 Greenhouse Gas Verification Annual Update Certification.

This demonstrates Hupao’s ongoing commitment to international standards, ensuring robust greenhouse gas management, and reflecting a long-term dedication to sustainable development, while continuously implementing carbon reduction and energy-saving initiatives.

Looking ahead, Hupao will continue to optimize its carbon management processes and work hand-in-hand with partners and clients to promote a green value chain, contributing to environmental sustainability.

We sincerely invite you to visit HU PAO INDUSTRIES CO., LTD. at the international event held in the United States —

The 2025 International Fastener Expo in Las Vegas, taking place from September 16 to 17, 2025!

Exhibition Name: 2025 International Fastener Expo, Las Vegas

Exhibition Dates: September 16–17, 2025

Venue: Mandalay Bay Convention Center

Address: 3950 S Las Vegas Blvd, Las Vegas, NV 89119, USA

Booth Number: 942

HU PAO cordially welcomes you to visit our booth,

We look forward to meeting you in person and exploring future opportunities together!

In order to reverse the public’s stereotype of dirty screw factories, GM Wang, who fully believes that enterprises should not only focus on profits but also bear environmental and social responsibilities, began to promote “net zero” in the fastener industry many years ago, and started with his own factory expansion to create a comfortable and safe workplace with low carbon emissions for all employees. He thinks that the disasters caused by climate change have become more serious than ever, and if people don’t do something, they are bound to affect our future generations.“Net zero can’t be just a lip service and change can only be made by breaking old rules,” says Wang. Such ideas can be implemented in fastener factories through 5S management, lean process management, digital carbon emission management, or improving high carbon emissions through organizations. He thinks that the spirit of net zero is sustainable coexistence, not to comply with regulations, but to demonstrate a company’s commitment to environmental protection and find a carbon reduction strategy that best suits its own size in the long run.

“CBAM is a challenge, but is also an opportunity for the industry to be transformed and redefined. If we can reduce the carbon emissions of countless fasteners around the world, we can transform ourselves from manufacturers into connectors to sustainability,” says Wang.

Under his leadership, Hu Pao has started to work with customers to design low-carbon products and develop alternative materials. “I hope to build a ‘Low Carbon Smart Factory Demo Base,’ and am also developing a more convenient carbon emission statistics system. In the future, I’d like to invite industry partners to set up a ‘Sustainability Alliance,’ so as to attract more people (especially young people) to change the fastener industry. Small screws support the world’s operation. If you are willing to do so, you can join us to transform the fastener industry into one that thrives with the environment and that you are proud to be a part of,” says Wang.